The Avid CNC Rotary Axis adds rotary cutting and indexing capabilities to PRO CNC and Benchtop CNC machines.

- Provides both the holding torque required for indexing operations, as well as the speeds sufficient for true rotary milling operations in a production environment.

- Self-contained within a rigid, all-metal framework to maintain precision alignment between the chuck and tailstock when changing workpieces, regardless of size, even when the entire axis is removed and reinstalled onto your CNC machine.

- Integrated precision linear rails allow for quick and easy setup for different workpiece sizes, while maintaining the precision alignment of the axis.

- Software-guided alignment that is fully integrated with our Auto-Z and Corner Finding Touch Plate.

- Integrated Pepperl + Fuchs inductive proximity sensor provides auto homing and workpiece alignment capabilities.

- Easy step-by-step assembly and calibration instructions

- Proudly designed and supported in the USA

Avid CNC Rotary Axis49" (1250mm) frame length

- 4 Jaw self-centering chuck, inside and outside jaws included

- Planetary gear reducer

- Adjustable tailstock, live center included

- Profile Linear Guide Rails and Bearings

- Low inductance Nema 34 stepper motor and cable (see product options below)

- Pepperl and Fuchs inductive homing sensor and sensor cable

- Aluminum frame, cut to length, drilled, counterbored, and tapped for easy assembly

- All required fasteners and gussets for mounting to your CNC machine (see product options below)

- 5” (130mm) 4 jaw chuck

- Morse Taper (MT) 2 tailstock with included live center

- Nema 34 stepper motor (N23 system compatible via provided motor adapter cable)[1]

- 10:1 Reduction

- Stall torque:

- 24 ft-lbs with Plug and Play NEMA 34 CNC Control System

- 20 ft-lbs with Plug and Play NEMA 23 CNC Control System

- Maximum RPM: 100

- Backlash: 3 arcmin

- Sensor Cable Length: 20'

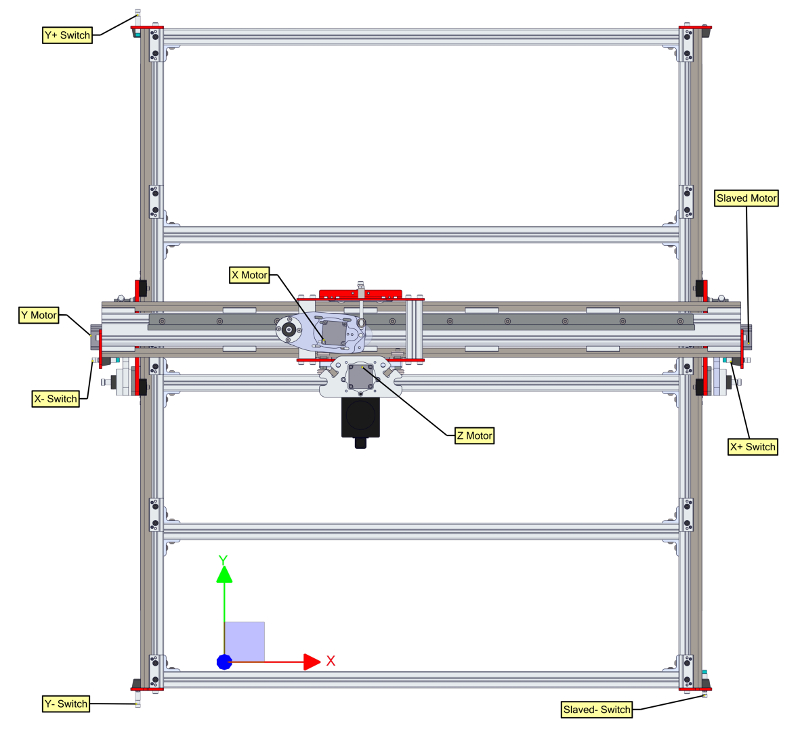

The Rotary Axis Kit is designed to be highly versatile and accommodate many different workpiece sizes, while maintaining traditional routing work areas.

It can be mounted to an existing machine parallel with the X or Y axis, or can be recessed into the machine frame to maximize workpiece diameter. Mounting parallel to the Y axis (perpendicular to the machine gantry) maximizes workpiece length, while mounting parallel to the X axis preserves greater traditional routing work area. Recessed mounting can only be achieved parallel to the X axis of the machine.

PRO Series CNC machine mounting options:[2]

- Table top, parallel or X or Y axis

- Recessed, parallel to X axis

Avid CNC Rotary Axis, table top mountedPRO4848 machine kit, 49" (1250mm) Avid CNC Rotary Axis, spoilboard, 2.2kW Spindle, NEMA 34 Motors

Avid CNC Rotary Axis, recessed mountedPRO4848 machine kit, 49" (1250mm) Avid CNC Rotary Axis, spoilboard, 2.2kW Spindle, NEMA 34 Motors

Benchtop PRO and Benchtop Standard mounting options:

- Table top, parallel to Y axis

Avid CNC Rotary Axis, table top mountedBTP2424 machine kit, 39" (1000mm) Avid CNC Rotary Axis, 2.2kW Spindle, NEMA 23 Motors

| Rotary Axis Frame Length | Maximum Workpiece Length | Minimum PRO Series Machine Width (Recessed Installation) | |

|---|---|---|---|

| Mounted Parallel to Y Axis | Mounted Parallel to X Axis (Recessed) | ||

| Inches (mm) | Inches (mm) | Inches (mm) | Feet |

| 39 (1000) | 24 (620) | N/A | N/A |

| 49 (1250) | 34 (870) | 28 (736) | 4 |

| 61 (1550) | 46 (1170) | 40 (1036) | 5 |

| 72 (1850) | 57 (1470) | 52 (1336) | 6 |

| 84 (2150) | 69 (1770) | 64 (1636) | N/A |

| 112 (2850) | 97 (2470) | 91 (2336) | n/a |

- Maximum swing over bed: 8" (when mounted directly to aluminum machine frame)

- Maximum swing over bed recessed: 12"

To determine the optimal rotary axis length for a specific application, start with the workpiece dimensions.

- Diameter 8" - 12": PRO Series machines only, recessed mounting required. See chart below for recommended rotary axis length.

- Diameter less than 8": Mounted parallel to X or Y axis on PRO Series machines, or parallel to Y axis on Benchtop machines. To achieve the maximum workpiece diameter of 8" with table top mounting, rotary frame must be installed directly to the machine frame (no spoil board underneath rotary axis). See chart below for recommended rotary axis length.

To gain complete access to the full Y travel of a machine, the rotary axis length must exceed the length of the machine frame (overall footprint will be affected). The chart below shows the required rotary axis length to maintain access to the full Y travel of the machine.

Mounting kits are available for both recessed and table top mounting:

- Recessed Mounting Kit includes:

- (2) Undermount bracket with jack screws for easy alignment of rotary frame

- (2) Mid-support bracket

- All fasteners required for recessed mounting

- Table Top Mounting Kit includes:

- (4) Gusseted corner bracket for mounting to machine frame or spoil board

- (1) Aluminum joining bar and bracket for fastening headstock to machine frame

- All fasteners required for table top mounting

Electronics are available for both Plug & Play and DIY control systems:

- NEMA 34 Plug and Play compatible option includes:

- (1) NEMA 34 960 oz-in stepper motor

- (1) 20'High Current CNC Motor Cable

- NEMA 23 Plug and Play compatible option includes:

- (1) NEMA 34 960 oz-in stepper motor

- (1) 20'High Current CNC Motor Cable

- (1) DB9 to XLR adapter cable

- DIY control system option includes:

- (1) NEMA 34 960 oz-in stepper motor

- (1) 20'High Current CNC Motor Cable

- (1) 7A Bulkhead Enclosure Connector

- The Avid CNC Rotary Axis uses a NEMA 34 960 oz-in stepper motor. A motor adapter cable will be provided to allow compatibility with NEMA 23 control systems. If your control system does not contain a 5th motor driver, please Contact Us for upgrade options. If you are purchasing one of our Plug and Play CNC Control Systems, select the "5th drive upgrade" option.

- When ordering a new PRO Series CNC Machine it is recommended to budget 2' of Y travel or 1' of X travel, in addition to your desired traditional routing work area for a permanently installed rotary axis. For example:

- 4' x 4' traditional work area with rotary axis mounted parallel to the X axis, a 4' x 6' machine is required

- 4' x 4' traditional work area with rotary axis mounted parallel to the Y axis, a 5' x 4' machine is required

- Avid CNC Rotary Axis Assembly and Calibration Instructions provide a full step-by-step guide to assemble and calibrate your rotary axis.

- Avid CNC Rotary Axis Footprints

Price: $2,470.00

New in: Avid CNC Rotary Axis

![CNC Software Setup Guide [Mach3] CNC Software Setup Guide [Mach3]](http://www.cncrouterparts.com/thumbnails2/ess_instructions.jpg)

![PRO CNC Plasma Instructions [Mach3] PRO CNC Plasma Instructions [Mach3]](http://www.cncrouterparts.com/thumbnails2/PRO_CNC_Plasma_Instructions.jpg)

![Auto Z and Corner Finding Touch Plate Instructions [Mach3] Auto Z and Corner Finding Touch Plate Instructions [Mach3]](http://www.cncrouterparts.com/thumbnails2/Auto_Z_Plate_Instructions_P1160970.jpg)