![PRO CNC Assembly Instructions PRO CNC Assembly Instructions]()

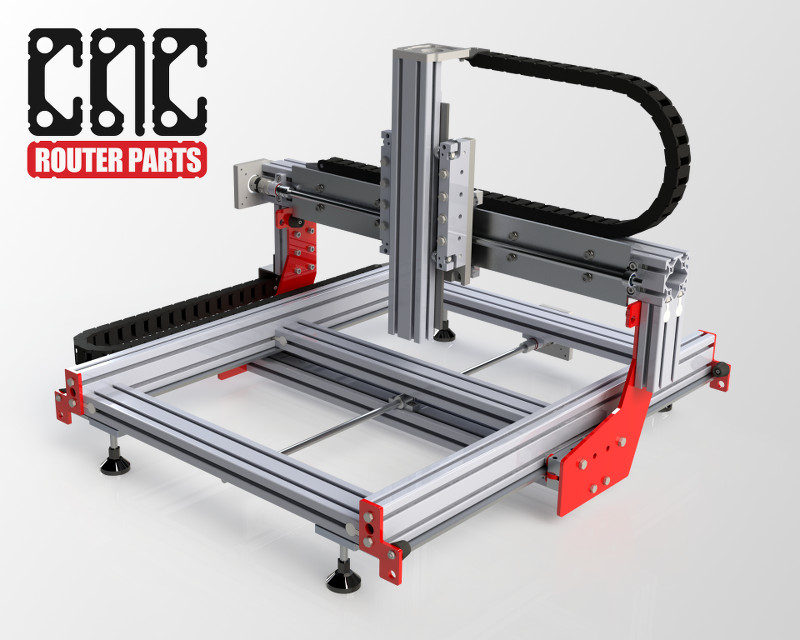

CNC Router Parts is proud to announce the release of a brand new 2016 revision of our PRO CNC line of large format CNC machines, debuting this weekend at Maker Faire Bay Area 2016.

We first launched the PRO CNC line in 2013 (also at Maker Faire!), and these have been great machines, serving hundreds of customers over the past three years, but we're always looking to improve. In that light, the newest kits will feature the following changes.

- Profile linear rails.

We invented the V-Con rail system to help make rugged, high quality linear motion affordable, and it has served well in this capacity. However, we’ve finally been able to source profile linear rails at a price that makes sense for our machine kits. While they are still more expensive, the simplicity and ease of assembly they offer justifies the modest increase in price to the kits. We will still offer individual V-Con components, but our PRO kits will be based on the new rail system. - New base fasteners.

We’ve changed the extrusion base design of our machines to use anchor counterbore fasteners, the stiffest connection method available that still maintains flexible positioning for machine cross-members. This connection method streamlines assembly and makes it easier to square the base of the machine during assembly. - Updated Z axis.

Our ballscrew Z axis has also been re-designed to use profile linear rails, and has additionally received a speed upgrade with 10mm pitch ballscrews (previously 5mm pitch screws). The axis has also been re-configured with fixed rails and a moving drop plate for routers or spindles, allowing for more usable travel, and providing a complete 8" clearance under the gantry, even with a 3” long tool installed. - Cable track is now included, standard.

We have traditionally offered a cable track (e-chain) as a optional kit for our machines, as we have had customers who want to build or engineer their own cable management solutions. While we will still offer this to the few customers who want to go this route, we have found over the past three years that the majority of our customers want a cable track solution included with their mechanical kit.

As always, whenever we revise our machine kits, we strive to make the new revision backwards compatible for current customers who wish to upgrade their systems, and this new revision is no exception. We will be offering multiple options for those interested. The new revision requires no changes to the overall frame of the PRO series (the series and lengths of the aluminum extrusion members have not changed).

New kits will officially be available for sale on June 1, 2016, and upgrade kits for previous versions of our PRO CNC machine will follow and become available 2-3 weeks after this.

Check in with us soon to see footage of the new machines in action at Maker Faire 2016!